pp.22–25

R P Singh kushwah1* and Dr.PBL Chaurasiya2

V G University Jaipur,

ICFAI University Jaipur

*Corresponding Author email: engineerrajp@gmail.com

ABSTRACT

The 70% Part of Marble is wastage in marble industry and responsible for many Sevier environmental problems. Only 30% recovery of product bears the remaining 70% burden. The marble waste is rarely degradable. So it is a wider environmental hazard. The water bodies and the rivers are also contaminated by flowing of marble slurry with rain water. This contaminated water affecting the irrigation and also the drinking water sources. Due to the presence of fine particles in marble slurry air is also polluted. Fines of Marble slurry flew with air blows creating serious health problem by breathing. Fine particles of marble slurry deposit over leaves of vegetation, plants and trees creating aesthetic problems. Due to deposition of marble dust over leaf the vegetation, plants as well as trees die, Hence loss of flora and fauna? The most efficient solution of marble slurry problem is the utilization in lot. Fineness modulus was found to be 0.91 and it is cohesion les material. According to this Marble slurry can be utilized in finishing work as White wash with lime. Which is 50% cheaper and also good Solar heat repellent causing natural building cooling.

Key words: – Environment, Cohesionles, Marble paste, White wash and Fineness modulus.

INTRODUCTION

Around 90% of the world’s production of marble comes from India and approx 85% of India’s production is received from Rajasthan and almost all mining and processing activities are concentrated around Makrana, where the proposed study is planned to undertake. Rajasthan has around 4000 marble mines and about 1100 marble gang saws (processing units). Alwar, Banswara, Chittorgarh, Sirohi, Jaipur districts etc are known for mining of marble. At the same time it leads to growth of many processing units in respective areas. These two activities in Rajasthan have been extended in 20-25 years and have played important role in the economy of the state providing direct and indirect employment to majority of people and therefore also raising their living standard. The industry involves mining and processing units for the production of tiles for walls and floors, articles, waste production and other ancillary works. The marble mining and the industry as a whole are different from other industries to the very fact that, the marble is a “Dimensional Product”, which means the Marble is sold by size not by weight (In other words in sqm not by tones). Since the selling price increases manifolds with size, all the operations involving mining and processing are aimed to get slabs as big as possible.

Marble slurry generation:-

Marble Slurry is a suspension of marble fines in water, generated during processing and polishing, etc. Environmental Hazards due to waste

It is shaping to major threat of the Environment in the state by mining and processing activities. Nearly one thousand Gang saws and thousands of cutters are producing 15-20 lack tons of marble slurry waste which is indestructible waste and harm to general Public. Some of effects of the marble slurry may be listed as under: –

- The waste is indestructibe.

- The sites which can be used as dumping ground are limited and give repulsive dirty look.

- Contamination of top fertile soil cover.

- Contamination of the rivers and other water bodies there by adversely affecting irrigation and drinking water resources.

- Contamination of air

Figure – 1: Loss of vegetation Figure – 2: Road side dumping

Public outcry, jurisdiction and intervention could deal deathblow to the growth of the marble industry. It is therefore a social and legal responsibility of government and industry to solve the problem of marble slurry pollution. As per Rajasthan High Court Petition No.2150/2004, it is violation of the provision of water prevention and control of pollution act 1974.

However, the development of country is only possible by sustainable balanced industrialization. Conservation of Natural Resources.

The valuable national wealth is getting wasted mainly due to lack of management and technology. This waste, if used, can change perhaps the entire scenario of the industry.

Air pollution.

This is the most hazardous impact of the marble industry. It is clear from the table 1, slurry is produced at almost every operation and it is a great problem. When it gets dry, it causes air pollution and related problems.

Water pollution.

Like any other industry, the marble industry needswater in its different operations for cutting, cooling and flushing. In these operations water gets contaminated by marble slurry.

Visual impacts.

Abandoned mines, dumping sites, slurry waste sites, deposition of dried slurry over almost every structure in surrounding areas gives a very bad, dirty look and aesthetic problem.

Accidents due to unscientific dumping.

Due to dumping of mine waste and marble slurry on road side causing dust in air (polluting air) and creating less visibility, due to less visibility number of accidents occurs. (refer figure no.2)

Accidents due to slippery roads.

In rainy season marble slurry flows over roads, due to marble slurry road becomes slippery and many accidents take place. (Refer figure no.2)

Loss to flora & fauna

Already grown trees and bushes die out and new ones do not grow due to deposition of marble slurry. Animals also suffer for their food and shelter (refer figure no.1)

AIMS AND OBJECTIVES:-

Utilization and scientific disposal of marble slurry on a properly selected dumping sight may be better solution of the problem. But now a day’s production increasing day by day the Utilization is the only solution of the problem. For this purpose the most useful steps can be: (A) Utilization (B) Disposal.

(A) Utilization of marble slurry:-

Even minimizing slurry production the problem could only be partially solved. Therefore it is the need to develop modes of utilization of slurry. Since other applications cannot consume such a bulk amount of slurry, efforts are being made to utilize slurry for different civil works.

Feasible Uses of Marble Waste

The areas where the utilization of marble slurry needs to be explored as a substitute for conventional raw materials are as follows:

As a filler material for roads and embankments.

For manufacture of bricks

Manufacture of Portland Cement

Manufacture of Ceramic Tiles

Manufacture of Thermo set Resin Composites

Manufacture of lime

Manufacture of Activated Calcium Carbonate

Hollow Blocks and Wall Tiles

Manufacture of Ground Calcium Carbonate

Curing with Marble Slurry. As Finishing material Marble slurry white washing with 50-50 Lime and Marble slurry.

(B) Disposal of marble slurry:-

Disposal is not permanent and better solution of the problem. So it is necessary to find out a Engineering solution like utilization in bulk.

Experiments:-

1. Fineness Modulus of Marble Slurry:- % Cumulative Retained  80

80

60

40

20

0

4.75 2.36 1.180.425 0.3 0.15 0.090.075

Sieve Size mm

Fineness Modulus = (1.41+2.42+9.27+18.15+8.87+39.72+12.10)/100 = 0.9194

Fineness Modulus = 0.91

All these three samples were tested for Smoothness, tuff ness, Moisture transmission and Shrinkage Cracks on surface.

The Second Sample Shown appropriate results, we have used it Interior as well as Exterior surfaces. Results of proportion of marble slurry mix in lime showing grades for graphical presentation of mix results with time.

Cumulative % Retained

- Water curing

- Membrane curing

- Application of heat

- Marble slurry curing.

This is by far the best method of curing as it satisfies all the requirements of curing, namely, promotion of hydration, elimination of shrinkage and absorption of the heat of hydration. It is pointed out that even if the membrane method is adopted, it is desirable that a certain extent of water curing is done before the concrete is covered with membranes.

Curing with marble slurry:

Spray of marble slurry fines cover and close the pores by which the water in the body to be cured is trapped inside and curing is completed. The Particles on the surface left was sticking to surface for long time with whiteness gave the idea to white wash with any binding material.

Study on Marble slurry white washing:-

- Designed Mix First:- The second sample prepared for testing was made with proportions as (1: 0.8) Lime : Marble Slurry.

- Designed Mix Second:- The second sample prepared for testing was made with proportions as (1: 0.9) Lime : Marble Slurry.

- Designed Mix Third:- The second sample prepared for testing was made with proportions as (1: 1) Lime : Marble Slurry.

- Designed Mix Fourth:- The second sample prepared for testing was made with proportions as (1: 1.1) Lime : Marble Slurry.

- Designed Mix Fifth:- The second sample prepared for testing was made with proportions as (1: 1.2) Lime : Marble Slurry.

All these three samples were tested for whiteness, stability, Moisture transmission.

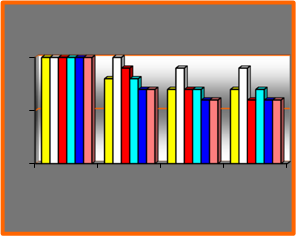

The third sample shown appropriate results on conducting study of 15 months on Patches of 1:0.8, 1:0.9, 1:1, 1:1.1 and 1:1.2 Mixed with marble slurry and a patch of Pure Lime. It was found that Patch of 1:1 (Lime: Slurry) was having shining, Not weathered as others. We have used it Interior as well as Exterior surfaces and the results was better. Results of proportion of marble slurry mix in lime showing grades for graphical presentation of mix results with time.

| GRADES | |||||

| S.NO

. |

BES

T |

BETTE

R |

GOO

D |

DUL

L |

BA

D |

| 1. | 10 | 9 | 8 | 7 | 6 |

GRADES

10  5 0

5 0

1st Qtr 2nd Qtr 3rd Qtr 4th Qtr

Lime(control)

Lime and Marble Slurry Proportion1:1 Lime and Marble slurry 1:0.8

Lime and Marble Slurry Proportion 1:0.9 Lime and Marble slurry 1:1.1

Time in Quarter Year

Conclusion:-

In Marble slurry white washing due to use of marble slurry with lime Cost reduces up to 50% and also more white & durab

Fineness modulus of Marble Slurry is 0.91 which allows it to be used for white washing making fine layer and white color repels heat resulting passive cooling of building.. Marble Slurry may be used for white washing for finishing work in construction Industry.

REFERENCES:-

- Rajasthan State Pollution Control Board, Jaipur (2010) office order by the member secretary, p14 (27) policy/RPCE/pig/4578-99 dated 4th March 2010.

- A K Mishra, Renu mathur, Y V Rao, A P Singh and Pankaj Goel, “A new technology of marble slurry waste utilization in roads” Journal of science & industrial research, vol 69, (2010).12 Bahar Demirel “The effect of the using waste marble dust as fine sand on the mechanical properties of the concrete”International Journal of the Physical Sciences Vol.5(9), pp.1372-1380, 18 August, (2010).

- 3. Helena lima, “Application of marble quarry waste in pavement layers” ICOR-Road construction institute, Portug

- RP Singh Kushwah “Solid Waste Engineering with Reference to Industrial Marble Waste of Rajasthan” Volume III, Issue V, May 2014 IJLTEMAS ISSN 2278 – 2540

- Kushwah al. ‘Utilization of Marble Slurry in Cement Concrete Replacing Fine Aggregate’ Scholar, SGV University Jaipur (India) American Journal of Engineering research (AJER) e-ISSN: 2320-084 p-ISSN: 2320-0936 Volume-04, Issue-1,pp-0-0