Ganesh Sonawane1*, Anurag Mishra1, Himmatsingh Chawra1, S. K. Singh1, Kajal Pansare2

1School of Pharmacy, Suresh Gyan Vihar University, Jaipur, Rajasthan

2Jagdamba Education Society’s, SND College of Pharmacy, Yeola, Nashik, Maharashtra

ABSTRACT

In today’s developing world, there is an immense need for novel drug delivery systems with minimal side effects. Natural excipients have an important role in developing drug delivery. They are safe, non-toxic, biodegradable, biocompatible, economical, and easily available as compared to synthetic. Medicinal plants are the gift of nature to have a disease-free healthy life to humans. Okra is one of the traditional plant-available worldwide. Its scientific name is Abelmoschus esculentus Linn., belonging to the family Malvaceae. The plant has rich nutritional value and is widely used in treating several human ailments. Mucilage is one of the important constituents isolated by extraction from the pods of okra. The okra mucilage has wide applications in different drug delivery systems as polymer. In the coming days, polymers will play important role in controlled drug delivery. This review article emphasizes on the role of okra mucilage in drug delivery systems.

KEYWORDS: Okra mucilage, Abelmoschus esculentus, Drug Delivery, Sustain-Release, Polymers.

INTRODUCTION

Now a day there is an immense demand for the plant as well as natural products compared to synthetic. Okra is one of the traditional and most useful crops due to its multiple roles. The plant’s leaves, buds, flowers, pods, stems, and seeds are all used in various ways. Okra is a flowering plant, also called ladies finger, bhindi, or bamia belonging to the family Malvaceae(1). Abelmoschus esculentus Linn. (A. esculentus) is the scientific name of okra. Earlier the plant was known as Hibiscus esculentus. Its origin is India but it is now grown in different areas of the world like the Middle East, Africa, and the Southern State of USA. The plant comes in different sizes like large, medium, and small, with lengths of over 15 cm, 10 to 15 cm, and 7 to 10 cm respectively.

Figure 1: Okra plant

The whole okra plant has numerous applications in food, non-food and medicinal applications. The seeds of okra have the nutritionally richest part of the plant, it has anti-oxidant property. The mucilaginous material found in the fruits, leaves, and stems has food and medicinal uses. The crude mucilage extract is made from the green stems of the mature okra plant. Okra mucilage is a glycoprotein that contains carbohydrates with about 80% of polymeric carbohydrates. Because of the hydroxyl group of sugar, okra mucilage has a high-water binding capacity. The fruits of the plants are generally harvested when it is at an immature stage and eaten in food as a vegetable. Okra seed oil is of essential nutritional value. The crude fiber found in mature fruit and stems is used in a variety of technologies(2). Natural mucilages are used as a binder, suspending agent, film floating agent, emulsifying agent, granulating agent, plasma expander, antiadhesive, stabilizer, thickening, and anti-oxidant in the pharmaceutical industry. In the area of drug delivery, natural mucilage is preferred over synthetic and semi-synthetic excipients because to their ease of availability, low cost, calming action, and non-irritant nature(3).

METHOD OF MODIFICATION

There are many modification techniques including curing, blending except grafting but modification using grafting techniques shows better results because of an enhancement of their physical and chemical properties. When a comparison is made between the conventional closed vessel techniques and the microwave-based grafting techniques, the microwave-based techniques are better as the polymer gets easily modified. Grafted copolymers have more capacity to hold water. These are capable of being recognized in controlled and sustained drug delivery systems. Due to its biodegradability, polymers are non-toxic and compatible with body fluids. There are various patents that have been approved for the modification techniques as well as for the grafted polymer-based inventions. These grafted polymers are not only found useful in pharmaceuticals but can also be used in numerous fields(4). Grafting polyacrylamide with Okra mucilage, a polysaccharide of vegetable origin, results in novel polymeric materials with industrially useful characteristics. Using Acrylamide (AAm) and N, N-Methylenebisacrylamide (NN-MBAAm), a redox initiator system of CAN/HNO3 is effectively applicable to graft and crosslink mucilage. The degree of grafting and crosslinking may vary dramatically depending on the monomer and initiator concentrations as well as reaction time and temperature. The grafting and crosslinking of acrylamide onto mucilage chains can be validated using several analytical techniques such as FTIR, SEM, and XRD patterns. The ability of crosslinked hydrogels to absorb water is affected by changes in pH. Because crosslinked polyacrylamides are non-biodegradable, utilizing polysaccharides to polyacrylamides improves the chances of biodegradable polymers forming. In comparison to pure polyacrylamides, graft copolymers of Okra mucilage and polyacrylamide appear to be more beneficial. Grafting merely improves the characteristics of mucilage by adding additional reactive sites without affecting the molecular mobility of polysaccharide chelating groups(5).

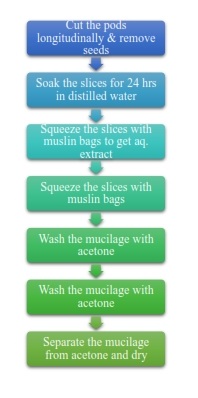

EXTRACTION OF OKRA GUM

Okra pods can be found in the local market. Cut the pods longitudinally into extremely thin slices, remove the seeds and soak for 24 hours in distilled water. Squeeze the swollen slices through muslin bags to produce an aqueous extract. To precipitate the mucilage, add twice the volume of alcohol to the aqueous extract. Using three times the volume of acetone, wash the mucilage. Separate the mucilage and filter out the acetone. Set a portion of the mucilage aside for solar drying(6).

Figure 2: Extraction of Okra gum

ROLE OF OKRA IN DRUG DELIVERY

As a binder

Okra gum is a binding ingredient that improves the hardness, friability and dissolution rate of several tablet formulations. This natural binder on the other hand slows the dissolution of some slightly soluble drugs and could be a potential choice for binding formulations. The binding property of Abelmoschus esculentus fruit polymer is significantly superior, according to the study(7). Compression coated tablets can be made using okra gum in various concentrations (3%, 4% & 5%) and three different grades of Hydroxypropyl methylcellulose (HPMC) in 30%, 60% and 90% concentrations. The swelling properties of the novel polymer okra can be demonstrated in the characterization and despite being a hydrophilic polymer, it may be applied successfully in sustained release formulations. Drug release can be successfully delayed if the reaction is zero order. The study provides an insight on the use of okra gum as a rate retardant polymer that can be employed successfully as a binder in table compression.

The study found that compression coated Losartan potassium tablets containing a natural okra gum and other hydrophilic polymers, such as HPMC, in various concentrations can delay drug release and despite being hydrophilic in nature, can prolong the therapeutic effect for up to 12 hours, establishing its superiority over similar dosage forms. The delay in drug disintegration caused by compressive coating is aided. Solvent-free coating minimizes the hazards of using coating ingredients and equipment while also proving to be beneficial. Once the outer layer is entirely dissolved through the mechanism of swelling and polymer relaxation, the presence of super-disintegrant allows for a quick onset of action. The gum yields granules with good micromeritic properties and tablets with good physicochemical qualities, according to the characterization. Its usage in continuous release drug delivery systems has been successful due to its swelling and rate retardant properties(6). Some tablet formulations utilizing okra gum as a binder have good hardness, friability, disintegration time and dissolution rate. This binder, on the other hand, slows down the dissolving rate of some weakly soluble drugs, making it a good choice for prolonged release formulations(8). The lower concentration levels of okra, according to the findings, can be employed as an alternate binder to starch. Okra mucilage in greater concentrations has a delayed and sustained release and can be used as an alternative natural excipient in modified drug delivery systems. At the same time, when the binder concentrations of Hibiscus mucilage are increased, the above natural excipient of Hibiscus mucilage might be exploited as a platform for sustained release(9). Propranolol hydrochloride utilizes as a model drug and the activity of okra gum as a binder is compared by making tablets with hydroxypropyl methylcellulose (HPMC) and sodium alginate, respectively, as a synthetic and semisynthetic binder. When comparing sodium alginate and HPMC for drug release kinetics, dissolution studies show that okra gum retards release by up to 24 hours and has the longest release time. Hardness and friability tests are also used to assess the tensile and crushing strength of tablets. Tablets made with okra gum have the highest hardness value and the lowest friability. As a result, okra gum is trusted as a successful adjuvant in the production of palatable prolonged-release tablets with high tensile and crushing strength(10). The mechanical properties of paracetamol tablets can be formulated with okra gum as a binder at the concentrations used is similar to those of povidone, gelatin, and HPMC. Okra gum is superior to the three binders in its ability to reduce brittle fracture tendency in paracetamol tablets and because it can achieve a very good drug release profile and mechanical properties at a low binder concentration range (1.0%w/w to 2.0% w/w) it should be better explored and exploited as an alternative to povidone in tablet formulation since the production would generally be cheaper; thus invariably leading to lower cost of tablet production(11)(12). Okra gum has been utilized as a binder, hydrophilic polymer matrix, suspension, and bio-adhesive agents, among other things(13). The mucilage of the A. esculentus pods has been reported to exhibit tablet-binding capacity(14),(15). In dental illness, A. esculentus has been found as a plasma expander, diuretic, and therapeutic agent. Plant mucilage has also been recognized as a tablet binder, in addition to its physiological functions. Only a limited investigation of the plant polysaccharide’s applicability as a gel-forming agent has been conducted thus far; consequently, the goal of this study was to assess the acceptability of okra polysaccharides as a gel-forming agent for the safe and effective delivery of pharmaceuticals via the nasal route(16).

As a suspending agent

One of the most desirable properties for the creation of pharmaceutical suspensions is the ability to suspend. Mucilage yields from A. esculentus and A. moschatus are essentially identical in quality, therefore the suspension properties of the mucilage, such as sedimentation volume, flow rate, particle size analysis, pH, and viscosity can be determined and mucilage can be utilized as a suspending agent(15). A. esculentus pod mucilage may be submitted to a pre-formulation study to determine its safety and suitability for use as a suspending agent. When paracetamol suspensions compared to different concentrations of A. esculentus mucilage, tragacanth gum, and sodium CMC (1%, 2%, 3%, and 4% w/v). Mucilage is a superior suspending agent than tragacanth and comparable to sodium CMC in terms of sedimentation profile, degree of flocculation, dispersibility, and rheological behavior. According to studies, the mucilage of A. esculentus can be utilized as a pharmaceutical adjuvant and a suspending agent at 4% w/v, depending on its suspending capacity and suspension stability(17). Okra mucilage works wonders as a suspending agent in the drug delivery system(2)(18)(14)(19). Okra mucilage has been used as a suspending and bio-adhesive agent (13). Okra mucilage has been used as a suspending agent in a variety of goods for decades in the food and confectionery industries. Okra mucilage’s superior water solubility and rheological properties in the aqueous media have led to its use as a possible pharmaceutical excipient material in a variety of pharmaceutical dosage formulations(20).

As a floating agent

Okra mucilage showed to be non-toxic, suitable, and capable of being used in the development of floating drug delivery systems. Repaglinide gastro-retentive tablets can be made using a three-level factorial design with naturally occurring plant-based polymers and a synthetic polymer combination. The batches of such tablets show good floatability, swelling index, and in vivo release properties. In vivo release studies demonstrate that formulating into a floating drug delivery system causes a decrease in the Ka and Ke, which is desirable for control release and the capacity to adjust pharmacokinetic behavior in the desired mode. In the development of controlled release dosage forms, plant-based polymeric can be a good substitute for synthetic polymers(21). Because of the matrix-forming ability of mucilage, A. esculentus fruit mucilage is one of the pharmaceutical excipients that allow for controlled drug release for a longer period of time by keeping the tablet floating in the gastric secretions. Because Abelmoschus gum is swellable, it can be used as a polymer in the development of a GRDDS alone or in conjunction with other polymers such as HPMC. However, the formulation using only A. esculentus gum is extremely appropriate for making floating matrix tablets because it showed a longer-lasting releasing effect. It should be noted that A. esculentus gum has a substantially higher floating capacity and longer release time than HPMC E 15 polymer. Metformin HCl floating tablets with A. esculentus aid to increase the residence time of Metformin HCl in the stomach by providing optimal floating time. This also helps to reduce the frequency of dosing, lowering the risk of side effects from Metformin, which is known to harm the kidneys(22). In a recent investigation, it is shown that Abelmoschus gum was used as a floating agent(19).

As a film coating agent

Okra gum samples with low viscosity can be obtained using the innovative extraction approach, they can compare to those acquired using the classic extraction method. These samples are effective film coating agents, delivering more solids in less time than those made using the traditional method(13). In the aqueous tablet film coating operation, okra gum is a potential natural, biodegradable, inexpensive, and environmentally friendly film former, especially when masking of flavor or disagreeable odor in a solid dose formulation is desired(23). Okra mucilage performs wonders as a film coating agent in drug delivery systems(2).

As an emulsifying agent

Mucilage from the waste of A. esculentus can be extracted using two different solvents and a modified hot extraction method (Acetone, Methanol). In terms of possible applications, they are superior to seaweed polysaccharides. When compared to methanol (11.3 % and 0.28 %; EC % = 50 %), macroalgae and okra waste have strong emulsifying power (EC % = 52.38 % and 54.76 %, respectively) with acetone (PH = 7)(24). Okra is high in vitamins and minerals that aid in the normal functioning of the human biological system. Okra is a miracle medical vegetable that contains a wealth of nutrients and can be used to treat a number of disorders. Antioxidant, antidiabetic, antihyperlipidemic, and antibacterial properties are all present in okra. Okra mucilage works wonders as an emulsifying agent in the drug delivery system(2). Mucilage from Abelmoschus containing information on an emulsifying property. Extraction of mucilage from Abelmoschus fruits or other plant parts, particularly from wild species, appears to be a profitable venture(15). One of the studies found that the okra plant might be used as an emulsifying agent in food emulsion systems(25).

As a plasma expander

The use of okra gum as a plasma expander has been studied. As a result, local pharmaceutical manufacturers should take advantage of this low-cost, high-quality pharmaceutical excipient that has been examined(12). In dental illness, A. esculentus has been found as a plasma expander, diuretic, and therapeutic agent(16).

As an antiadhesive

To treat gastritis, traditional African and Asian medicine uses immature okra fruits as a mucilaginous food. Its efficiency is due to polysaccharides, which prevent Helicobacter pylori from adhering to stomach tissue. Strong antiadhesive effects are caused by non-specific interactions between high molecular components from okra fruits and the surface of H. pylori(26).

As a stabilizer

- esculentus mucilage is non-toxic and has the ability to act as a stabilizer(17). Both A. esculentus and A. moschatus have palatable mucilage that could be used as pharmaceutical adjuvants at lower concentrations (0.5-2 % w/v). Because of these characteristics, A. esculentus mucilage has been proposed for use as a stabilizer in the cosmetic, pharmaceutical, and food industries(15). Okra gum has been used as a foam stabilizer in a variety of products in the food and confectionery industries in recent years(20). Okra gum is also employed as a viscosity supplementation agent in osteoarthritis treatment, tablet binding and disintegrating agent-controlled drug delivery systems, slimming aids, nutritional foods, and other transdermal drug delivery systems. Biodegradability, biocompatibility, and easy availability of okra gum encourage most scientists to focus their work on it. Okra gum is an economical stabilizer(27).

As a thickener

The cellulose and uronic acid-containing polysaccharides in okra mucilage can be acid hydrolyzed to produce l-arabinose, d-galactose, l-rhamnose, d-galacturonic acid, and d-glucose. Mucilage from the seed coat of L. sativum possesses thickening and gelling properties(14).

As an anti-oxidants

Gemede et al. in their study found that pods of okra accessions possess a desirable level of mucilage and are possible natural antioxidant sources(28). Fresh and dried okra seeds have higher protein (19.20 %) and lipid (12.72%) content than okra pods, which have protein (5.43 %) and fat (8.19 %). Antioxidant tests revealed that okra fruit and seed are high in phytochemicals. Okra is a rich source of natural antioxidants since it contains a high quantity of total flavonoids and a moderate amount of total phenolics. Okra pod and seed extracts should be considered as an antioxidant supplements to other products based on their antioxidant properties(29).

Figure 3: Role of Okra Mucilage in Drug Delivery

CONCLUSION

The data gave here demonstrate that okra is an essential vegetable crop that plays a variety of roles in drug delivery. Moreover, the polysaccharide content of the fruit has piqued the interest of research in the food and pharmaceutical industries. Furthermore, rather than being confined exclusively to the kitchen, this vegetable can be used as a vital tool in the prevention of many diseases.

REFERENCES

- Georgiadis N, Ritzoulis C, Sioura G, Kornezou P, Vasiliadou C, Tsioptsias C. Contribution of okra extracts to the stability and rheology of oil-in-water emulsions. Food Hydrocoll. 2011;25(5):991–9. Available from: http://dx.doi.org/10.1016/j.foodhyd.2010.09.014

- Das S, Nandi G, Ghosh LK. Okra and its various applications in Drug Delivery, Food Technology, Health Care and Pharmacological Aspects-A Review. J Pharm Sci Res. 2019;11(6):2139–47.

- Sangwan YS, Sngwan S, Jalwal P, Murti K, Kaushik M. Mucilages and Their Pharmaceutical Applications: an Overview. Pharmacologyonline. 2011;2:1265–71.

- Attri A, Kumar R, Rozera R, Sudhakar CK, Vyas M, Wadhwa P, et al. A systematic review on grafting techniques and their applications with reference to natural gums and mucilage. Plant Arch. 2019;19:979–82.

- Mishra A, Clark JH, Pal S. Modification of Okra mucilage with acrylamide: Synthesis, characterization and swelling behavior. Carbohydr Polym. 2008;72(4):608–15.

- Chatterjee S, Mazumder. Formulation and Evaluation of Losartan Potassium Compression Coated Tablets By Okra Gum As a Binder. Int J Pharm Sci Res. 2019;10(6):2917–22.

- Biswal B, Karna N, Patel R. Okra mucilage act as a potential binder for the preparation of tablet formulation. Der Pharm Lett. 2014;6(3):31–9.

- Tavakoli N, Ghasemi N, Hamishehkar H. Evaluation of Okra Gum As a Binder in Tablet Dosage Forms. Iran J Pharm Res. 2004;3(2):47–47.

- Ameena K, Dilip C, Saraswathi R, Krishnan PN, Sankar C, Simi SP. Isolation of the mucilages from Hibiscus rosasinensis linn. and Okra (Abelmoschus esculentus linn.) and studies of the binding effects of the mucilages. Asian Pac J Trop Med. 2010;3(7):539–43. Available from: http://dx.doi.org/10.1016/S1995-7645(10)60130-7

- Zaharuddin ND, Noordin MI, Kadivar A. The use of hibiscus esculentus (Okra) gum in sustaining the release of propranolol hydrochloride in a solid oral dosage form. Biomed Res Int. 2014;2014.

- Kulkarni PK, Reddy S, Biswal B, Karna N, Patel R, Ahuja M, et al. Mucilages and Their Pharmaceutical Applications: an Overview. Indian J Pharm Sci. 2014;2(2):415–22. Available from: http://dx.doi.org/10.1016/j.ijbiomac.2014.01.008

- Ebere I. Okoye, Anthony O. Onyekweli and 2Olobayo O. Kunle. Okra gum- an economic choice for the amelioration of capping and lamination in tablets 1. Ann Biol Res. 2011;2(2):30–42.

- Ogaji I, Hoag S. Novel extraction and application of okra gum as a film coating agent using theophylline as a model drug. J Adv Pharm Technol Res. 2014;5(2):70–7.

- Prajapati VD, Maheriya PM, Jani GK, Patil PD, Patel BN. Lepidium sativum Linn.: A current addition to the family of mucilage and its applications. Int J Biol Macromol. 2014;65:72–80. Available from: http://dx.doi.org/10.1016/j.ijbiomac.2014.01.008

- Nair BR, Fahsa. Isolation and characterization of mucilage from some selected species of Abelmoschus medik (malvaceae) and their application in pharmaceutical suspension preparation. Int J Pharm Pharm Sci. 2013;5(1):398–402.

- Sharma N, Kulkarni GT, Sharma A. Development of abelmoschus esculentus (Okra)-based mucoadhesive gel for nasal delivery of rizatriptan benzoate. Trop J Pharm Res. 2013;12(2):149–53.

- Kumar R, Patil MB, Patil SR, Paschapur MS. Evaluation of Abelmoschus esculentus mucilage as suspending agent in paracetamol suspension. Int J PharmTech Res. 2009;1(3):658–65.

- George B, Suchithra T V. Plant-derived bioadhesives for wound dressing and drug delivery system. Fitoterapia. 2019;137.

- Shirwaikar A, Shirwaikar A, Prabhu S, Kumar G. Herbal excipients in novel drug delivery systems. Indian J Pharm Sci. 2008;70(4):415–22.

- Nayak AK, Ara TJ, Saquib Hasnain M, Hoda N. Okra gum–alginate composites for controlled releasing drug delivery. Applications of Nanocomposite Materials in Drug Delivery. Elsevier Inc.; 2018. 761–785 p. Available from: http://dx.doi.org/10.1016/B978-0-12-813741-3.00033-9

- Naveen NR, Gopinath C, Rao DS. Design expert supported mathematical optimization of repaglinide gastroretentive floating tablets: In vitro and in vivo evaluation. Futur J Pharm Sci. 2017;3(2):140–7. Available from: https://doi.org/10.1016/j.fjps.2017.05.003

- Chodavarapu NP, Yendluri RB, Suryadevara H. Available Online through Formulation and Evaluation of Abelmoschus Esculentus. 2011;3(2):2725–45.

- Ogaji I, Nnoli O. Film coating potential of okra gum using paracetamol tablets as a model drug. Asian J Pharm. 2010;4(2):130–4.

- Archana G, Sabina K, Babuskin S, Radhakrishnan K, Fayidh MA, Azhagu Saravana Babu P, et al. Preparation and characterization of mucilage polysaccharide for biomedical applications. Carbohydr Polym. 2013;98(1):89–94. Available from: http://dx.doi.org/10.1016/j.carbpol.2013.04.062

- Noorlaila A, Siti Aziah A, Asmeda R, Norizzah AR. Emulsifying properties of extracted Okra (Abelmoschus esculentus L.) mucilage of different maturity index and its application in coconut milk emulsion. Int Food Res J. 2015;22(2):782–7.

- Messing J, Thöle C, Niehues M, Shevtsova A, Glocker E, Borén T, et al. Antiadhesive properties of Abelmoschus esculentus (okra) immature fruit extract against Helicobacter pylori adhesion. PLoS One. 2014;9(1).

- Vidyanagar V. Synthesis, Characterization and Optimization of Reaction Parameters for Sodium Salt of Partially Carboxymethylated Okra Gum. Chem Sci Trans. 2018;7(1):55–62.

- Gemede HF, Haki GD, Beyene F, Rakshit SK, Woldegiorgis AZ. Indigenous Ethiopian okra (Abelmoschus esculentus) mucilage: A novel ingredient with functional and antioxidant properties. Food Sci Nutr. 2018;6(3):563–71.

- Mir TA, Boked HR, Wani NA, Lone MA, Bhat PA. Investigating Fresh and Dried Okra (Hibiscus Esculentus) for their Physico-Chemical and Antioxidant Properties : A Comparative Study. Int J Res Appl Sci Eng Technol. 2017;5(V):562–71.